Abstract

Electrostatic sprayers, when combined with the proper chemistry and conditions, work by

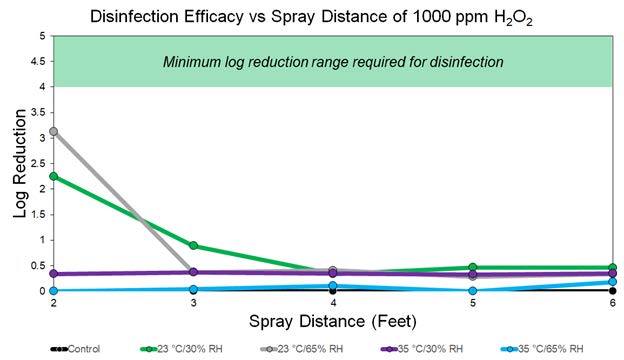

positively charging disinfectant droplets so that when they are sprayed, they seek out and cling to negatively- or neutrally- charged surfaces. This allows for even and thorough surface coverage of the disinfect in a given facility, including difficult to reach areas that traditional spray and wipe methods tend to miss. In a forthcoming study commissioned by TIPS (now known as GBAC-TIPS), the efficacy of electrostatically sprayed disinfectant on the superbug Methicillin-Resistant Staphylococcus aureus (MRSA) was evaluated as a function of spray distance of the target surface, temperature, and relative humidity. The preliminary findings reveal that not only the spray distance, but temperature and relative humidity of the room may be important variables to factor in when considering proper disinfection protocols. At near ambient conditions (temperature: 23°C; RH 35%), a log reduction of ~3 of the MRSA bacteria was achieved. However, as temperature, distance, and humidity increases, detrimental effects are observed across the board with major reductions in efficacy. This study will lead to further research to determine the best way to adjust for spray distance, temperature, and relative humidity when using an electrostatic sprayer to disinfect a facility.

Synopsis

Service providers that disinfect public spaces have a fiduciary duty to their customers and the public at large to provide a safe, clean space in the most efficient way possible. Electrostatic spraying of EPA approved disinfectants offers a rapid way to achieve both when done properly. However, there are major unaddressed concerns regarding the validation of sprayer and chemistry combinations as it pertains to accounting for environmental parameters, including chemistry concentration, spray distance, spray time, nozzle flow rate, temperature, relative humidity, wind speed, etc. The lack of characterization of such factors and their impacts on disinfection efficacy leads into broader concerns of accurate spray training, maintenance, and auditing with respect to proof of work, including:

- Insufficient protocols, guidelines and standards addressing how chemistry should

be applied when utilizing an electrostatic sprayer may create discrepancies and

misunderstandings in concentration and spray distances required. - Lack of scalable methods of showing if the concentration of a disinfectant remains

consistent enough on the surface once sprayed to satisfy kill claims. - Maintenance issues, improper refill practice, cleaning of equipment and

overheating during surface application. - Improper training and guidelines to determine correct calculations for different

environments can lead to wasted chemical sprayed due to over spraying and/or

premature evaporation. - Lack of standardized auditing measures that track workers on a routine basis for

consistency in cleaning and disinfection technique and performance.

For this initial study, the primary focus was to characterize and evaluate in a controlled

environment the effectiveness of inactivating Methicillin-Resistant Staphylococcus aureus

(MRSA) to a minimum of log 4 reduction at varying distances as a function of temperature and relative humidity of the room. The testing performed was a modification to the US EPA’s MB-06-09, Standard Operating Procedure for Germicidal Spray Products as Disinfectants (GSPT): Testing of Staphylococcus aureus, Pseudomonas aeruginosa, and Salmonella enterica. The test results shown below (figure 1) reveal that at 1000 ppm H2O2 was unable to reach log 4 reduction under any given parameter of the experiment, only achieving a best of log 3.13 reduction at 23 °C/65% RH. At 23 °C, efficacy was reduced dramatically from 2 to 3 feet, rendering the application largely ineffective. As the temperature is increased in combination with an increase in relative humidity, the application of the disinfectant is completely ineffective.

Figure 1: Log reduction plot of MRSA as a function of spray distance at varying conditions.

Final publication of study is expected in early 2022.