Disclosure statement: InfectionControl.tips declare no conflict of interest with the following critical evaluation and research. No funds or influence were provided to InfectionControl.tips by any parties.

Abstract

There are numerous solutions for reducing the risk of respiratory illness for potable water systems from Legionella pneumophila and other opportunistic organisms. One is to first start with filtration of the incoming source water for particulates. Dirt and sediment can reduce the efficacy of disinfectants, reducing its bacetericidal potency. Since L. pneumophlia growth is more prevalent in the hot water system, the hot water should also have microbial reduction filtration. These recommendations should also extend to water cooling towers, where they should be filtered for sediment and microbial contaminates.

Main Article

The CDC has reported that Legionnaires’ disease has increased over 4.5 times from 2000- 2015 (Centre of Disease Control, 2017). Legionnaires’ disease is primarily caused by Legionella pneumophlia bacteria when present as an aerosol (Centre of Disease Control, 2017). Outbreaks have been linked to contaminated, poorly maintained water sources in many hospitals and long-term care (LTC) homes (Center for Medicare and Medicad Services, 2017). The CDC has published a Legionella tool kit which is designed to provide a practical guide for implementing industry standards, most notably the latest industry standard ASHRAE 188 Legionellosis: Risk Management for Building Water Systems (Centre of Disease Control, 2017). The CDC guide is designed to assist building owners in developing a water management program to reduce Legionella growth & spread in buildings. This guideline provides building owners/managers a template to produce a Water Management Plan for the facility. It provides suggestions for identifying areas within the building to monitor temperature, residual disinfectants and pH with suggested control limits for each. It also suggests periodic testing for Legionella pneumophlia and corrective action, when contamination control limits are not maintained (Centre of Disease Control, 2017). While these industry standards and policies are certainly a step in the right direction and will surely improve identification of the problem sites, monitoring, corrective action and verification of the building it cannot eliminate the outbreaks for Legionnaires’ disease.

Central treatment plants face the problem of distributing potable water to each end user through nearly one billion miles of underground piping. Regardless of the water quality produced at the plant getting it to the end user is dependent on the quality of the distribution systems. The EPA contracted the National Research Council to produce study on “Public Water Supply Distribution Systems: Assessing and Reducing Risks” (National Research Council, 2005). This report clearly identifies the water quality issues attributed to distribution systems and includes, the EPA estimate costs for next 20 years for water transmission and distribution repair to be $83 billion (National Research Council, 2005)..

It is the responsibility of the Public Water Supplier (PWS) to notify its customers when water quality is at risk due to failures in the distribution system or upsets at the plant. Identification of these failures cannot be detected 100% of the time, but when identified the PWS issues public notice of the problem. As a result, the PWS cannot guarantee safe water 100% of the time. Therefore, it behoves the facility managers to proactively manage their potable water within the premise plumbing as well as any cooling towers.

Legionella grows best at temperatures between about 20°C and 50°C (68°F and 122°F)

Legionella grows best at temperatures between about 20°C and 50°C (68°F and 122°F). Many areas of the building water system contain water within this temperature range (ASHRAE, 2005). One approach is to raise the temperature in the hot water potable system to greater than 158 degrees Fahrenheit (◦F) to kill Legionella and other organisms (US Department of Energy, 2005). This approach requires that the hot water be tempered downstream to prevent scalding. Temper reducing valves that blend cold water can be installed to lower the temperature at the distal sites to less than or equal to 120◦F. to prevent scalding (American Burn Association, 2006). This temperature does not kill Legionella. Therefore, if the cold water being blended is not treated for Legionella it can contaminate the hot water after this blending process. The cold-water supply then becomes the primary target for reduction of microbial levels in the water supply. Legionella colony growth is seen in water temperatures from 68-122 ◦F but can survive outside of this range (American Burn Association, 2006).

Current Treatment Solutions for Buildings Potable Water System

Secondary Disinfection | Using chemicals, copper/silver ionization or ozone

Secondary disinfection using chemicals (chlorine, chlorine dioxide, mono-chloramine), ozone or copper/silver ionization (CSI) are generally installed on the hot water potable water system, since this area has the greatest potential for Legionella growth. Field test kits are available to monitor for the levels of the chlorines and ozone disinfectants. However, CSI requires testing at approved lab using EPA Method 200.8 for copper and silver levels (Shannon et al, 2008). Testing the water for the available level of the disinfectant at several distal sites is then used to adjust the systems dosing levels. The ability of maintaining disinfectant level can be greatly impacted by the source water quality and contact time.

Dirt/sediment, microbial load and other contaminants will increase the demand for disinfectant and can result in higher demand of dosage of disinfectants( Shannon et al, 2008). Removal of these contaminants can reduce the dosage requirements and provide a detectable residual level. The maximum disinfectant and disinfectant by product (DBP) levels are regulated by the United States Environmental Protection Agency (U.S. EPA) Safe Drinking Water Act. Chlorine, chlorine dioxide, mono-chloramine and ozone all can create DBP’s which are regulated by U. S. EPA (Cordero et al, 2016). Stagnant water pipes and dead-end plumbing can prevent the disinfectant from reaching these areas. This results in low or no disinfectant being available to these areas. Periodic flushing of these areas can help to maintain a disinfectant level and reduce microbial risk levels. The measuring of ozone levels is difficult due to its short half-life and breakdown in hot water therefore it is normally used along with one of the above chemical solutions. Ozone is toxic in the air. so excessive levels must be vented outside of the building (Cordero et al, 2016).

All the above solutions can cause unwanted issues for the potable water system such as, corrosion, pitting of piping, DBP’s or taste/odor complaints. CSI can result in high levels of copper/silver metals which can exceed the U. S. EPA maximum contaminants levels (MCL). USEPA (EPA 810-R-16-001 September 2016 (Cordero et al, 2016).. Several state regulatory agencies are defining chemical, ozone or CSI treatment witin the premise plumbing as secondary disinfection. This designation can subject them to being classified as a “public water system” as defined in the Safe Drinking Water Act (Environmental Protection Agency, 2017). The USEPA used section 1419(b) of the Safe Drinking Water Act (SDWA), to implement a certified water plant operator program for all public water systems (Environmental Protection Agency, 2017). If the facility gets classified as a public water system it will add significant cost of operation. A certified plant operator is required to manage the system with few exceptions. This cost will vary depending on the size of facility and geographic location. Any U.S. state may elect to exercise oversite of potable water premise systems that add chlorine, chlorine-dioxide, mono-chloramine, CSI, or ozone treatment within their facility. The added cost of this oversite will discourage many facilities from using these solutions.

Secondary Disinfection without chemical or other disinfectants

Ultraviolet (UV) Disinfection dose requirements in millijoules per centimeter squared (mJ/cm2) of 186mJ/cm2 provides a >4 log reduction value (LRV) of protozoan cyst such as cryptosporidium and virus [EPA UV Disinfection Guidance Manual (UVDGM) for the final LT2ESWTR table 1.4] (Oguma et al. 2004). Bacteria is killed at much lower doses than protozoan or viruses and therefore the UVDGM does not specify dose level requirements for bacteria. L. pneumophlia 4 LRV kill or inactivation is achieved at 6.4 mJ/cm2 (Oguma et al. 2004). UV does not provide a residual disinfectant within system that can be measured and therefore a small chlorine residual in the plumbing is recommended.

POU (Point of Use) and POE (Point of Entry) microbial and particulate filtration rely on mechanical and or electro-absorptive charged membranes to remove the dirt, cysts and microorganisms. They are currently not considered secondary disinfection, and therefore are not currently being regulated in the U.S. The US EPA conducted a literature review of treatment options for the above methods and other treatment options for Legionella risk reduction but did not address the source water or sudden changes in water quality (Environmental Protection Agency, 2017).

Waterline Technology Solutions for a Premise Plumbing in Potable Water System

POE Treatment | Filtration

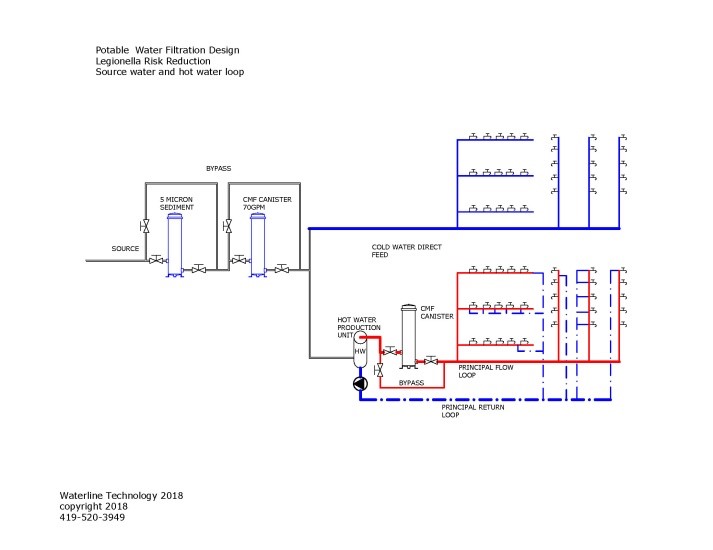

Figure 1: The basic design suggested for the potable water system (Waterline Technology)

POE Cold water supply | Filtration Solutions

Waterline Technology suggests that the entire buildings incoming water supply is filtered. Stage 1 is a prefilter (5 micron filter) for the removal of dirt/sediment and Stage 2 filter is for removal of microorganisms, including Legionella (Waterline Technologies, 2018). This filtration of the source potable water does not remove the incoming disinfectant levels maintained by the Public Water System. This supply of filtered water, for all cold water feed plumbing systems, will provide >99.9% removal of dirt/sediment and bacteria, virus and cysts (Waterline Technologies, 2018).

Sizing of the flow rate is crictical to insure the proper filtration vessels are installed to prevent low flow to the building. Pressure differential (PSID) is used to determine the cartridge’s life cycles, which is set to 35 psi. This stand alone filtration has been performance tested for Raoultella terrigena, MS2, L. pneumophlia and cysts (Waterline Technologies, 2018).

Even though cold water (<68 ◦F) does not promote the growth of Legionella and other organisms, they can still continually contaminate the plumbing if this source water filtration is not in place (Zeigler, 2015). This contamination can be extreme during upsets to the source water supply due to boil orders, high turbidity and other issues not known to the building management until after the fact. Filtering the source water entering the building to reduce dirt/sediment and microbial contaminants from PWS will insure that cold water for cooling towers, temperature control valves, misters etc all benefit from this initial log reduction values!

POE Treatment | Hot Water Filtration Solutions

Hot Water Recirculation Loop

Many building will use a recirculation pump for the of hot water to reduce the time required for distal sites to have hot water. It is recommended that a microbial filter be installed into this recirculation loop or after hot water storage tank if hot water recirculation is not available. The microbial retention performance will increase significantly since it is constantly recirculated. With the source water filtration installed, this becomes a redundant microbial filter, since the cold-water supply to the hot water is also being filtered. This constant filtering of the hot water loop controls the microbial load. A hot water recirculation loop provides us with an optimum design to constantly keep the hot water loop clean and safe. If stagnant water at distal sites continue to test positive for microbial levels, then POU filtration can selectively be installed on those sites and manual or automatic flushing of these sites may be implemented to remove the stagnant water and provide fresh filtered water.

Specification of Filtration | Design considerations

Dirt/Sediment filters

Particulate Size Distribution (PSD) test should be conducted to determine the proper micron size required for Stage 1 filtration. Using laser technology, the size and quantity of dirt/sediment particles can be quantified. Then sizing the filter for the micron size will result in performance required to remove the dirt/sediment or sometimes referred to as turbidity.

Microbial filters

There are numerous technology options for filtering microbial contaminates, such as Ultra-filtration membranes, Sub micron filters (note not effective for virus removal), and Electro-adsorptive filters used in the industry. Electro-absorptive filters require the lowest pressure and do not require backwashing that can provide > 4 LRV of virus and >6 LRV bacteria and >5 LRV protozoan cysts (Silva et al, 2018).

Point of Use (POU) Treatment Solutions

Ice makers, humidifier, misters, decorative fountains, etc.

Water filtration can be installed on distal sites with continual microbial problems that are fed with cold water. POU filters can provide long life (6-12 months) and high LRV (log reduction values) with simple installation and quick release sanitary cartridge changes are available. Flow rates of 2-5 gpm can normally supply the ice maker, misting systems, humidifier, and sink faucets (Zeigler 2018).

Cooling Tower System

The open circuit cooling towers recirculate the water and it is returned to the tower (US Department of Energy, 2011). They can be continually contaminated by environmental issues due to the design which use outside air for cooling. This air flow can consist of microbial and suspended solids that contaminate the wetted parts and reduce the water quality within the tower during normal operation. Cooling towers represent a major contributor to Legionella outbreaks and airborne microbes can travel great distances in the air. The bacteria from the cooling towers are dissipated to the atmosphere through the evaporation process (US Department of Energy, 2011).

Cooling towers present the perfect environment for biological activity due to the warm, moist environment. The DOE describes two distinct categories of biological activity in the tower. The first being planktonic, which is bioactivity suspended or floating in solution. The other is sessile bio-growth, which is the category given to all biological activity, biofilms or biofouling that stick to the surface of the cooling system (New York City Department of Health And Mental Hygiene, 2016).

Some states have adopted parts of ASHRAE 188 and are requiring licensing and inspections of the cooling towers. This has been slow to be implemented and controlling the biocide residual levels is greatly impacted by the microbial and dirt load which is constantly changing (ASHRAE, 2015).

Verification of Performance

Potable water & cooling tower

There are several tests that are recommended in ASHRAE 188, with recommended response actions when results exceed control limits. Monitoring the temperature and residual disinfectant is also highly recommended. The first test is Heterotrophic Plate Count (HPC), with control limits of <200 CFU/mL (ASHRAE, 2015). HPC testing can establish a base line indicator of microbial levels and can be done on a routine basis (weekly or bi-monthly). This test does not identify the organisms but can be used to monitor any spikes in levels to take corrective action. HPC testing cost is much less than testing for Legionella. Legionella pneumophlia testing be completed, with a goal of <1 CFU/mL, when HPC levels exceed control limits and or to verify the treatment process for the potable water (ASHRAE, 2015).

Summary

It is recommended that every building develop a Water Management Program that closely follows ASHRAE 188 standards for potable water system and cooling towers. While testing provides data of the health of the premise’s plumbing and cooling towers, the probability of L. pneumophlia and other opportunistic pathogens being present suggest treatment should be in place to protect the water systems at all times. A proactive approach that includes water filtration of the source water, hot water for potable water systems and continuous filtration of the cooling tower for Legionella and dirt/sediment Is recommended. Monitoring of, HPC counts and L. pneumophlia counts, temperature and disinfectant levels combined with corrective action for areas outside of control limits will reduce the Legionella Risk in potable water and cooling towers.

References

- Center for Disease Control (2017) Developing a Water Management Program to Reduce Legionella: A Practical Guide to Implementing Industry Standards Growth & Spread in Buildings. Centre for Disease Control. Accessed March 26, 2018 https://www.cdc.gov/legionella/downloads/toolkit.pdf

- Center for Medicare and Medicaid Services (2017) Requirement to Reduce Legionella Risk in Healthcare Facility Water Systems to Prevent Cases and Outbreaks of Legionnaires’ Disease (LD). Centre for Medicare and Medicaid Services. Accessed March 26, 2018 https://www.cms.gov/Medicare/Provider-Enrollment-and-Certification/SurveyCertificationGenInfo/Downloads/Survey-and-Cert-Letter-17-30.pdf

- National Research Council (2005) Public Water Supply Distribution Systems: Assessing And Reducing Risks. National Academic Press. https://www.nap.edu/read/11262/chapter/1

- ASHRAE (2005) ASHRAE Guide 12-2000 , American Society of Heating and Air-Conditioning Engineers. https://www.techstreet.com/ashrae/standards/guideline-12-2000-minimizing-the-risk-of-legionellosis-associated-with-building-water-systems?product_id=232891

- American Burn Association (2006) National Safe Kids Campaign. American Burn Association.http://ameriburn.org/wp-content/uploads/2017/04/scaldinjuryeducatorsguide.pdf

- Shannon, M. A., Bohn, P. W., Elimelech, M., Georgiadis, J. G., Marinas, B. J., & Mayes, A. M. (2008). Science and technology for water purification in the coming decades. Nature, 452(7185), 301.

- Cordero C et al, (216) Technologies for Legionella Control in Premise Plumbing Systems: Scientific Literature Review. Environmental Protection Agency/ https://www.epa.gov/sites/production/files/2016-09/documents/legionella_document_master_september_2016_final.pdf

- Environmental Protection Agency (2017) Safe Drinking Water Act (SDWA). Environmental Protection Agency. https://www.epa.gov/sdwa

- Oguma, K., Katayama, H., & Ohgaki, S. (2004). Photoreactivation of Legionella pneumophila after inactivation by low-or medium-pressure ultraviolet lamp. Water Research, 38(11), 2757-2763.

- Waterline Technologies (2018) AlwaysFresh Product Comparison. Waterline Technologies http://www.waterlinetechnology.com/comparison.html

- Zeigler A (2015) Disinfection: Precautions For Microbial Reduction. Water Quality Products. https://www.wqpmag.com/disinfection-precautions-microbial-reduction

- Silva, R. G., Szabo, J., Namboodiri, V., Krishnan, E. R., Rodriguez, J., & Zeigler, A. (2018). Evaluation of an environmentally sustainable UV-assisted water treatment system for the removal of Bacillus globigii spores in water. Water Science and Technology: Water Supply, 18(3), 968-975

- US Department of Energy (2011) Cooling Towers: Understanding Key components of Cooling Towers and How to improve water efficiency. US Department of Energy https://www1.eere.energy.gov/femp/pdfs/waterfs_coolingtowers.pdf

- New York City Department of Health And Mental Hygiene (2016) Notice of Adoption of Chapter 8 (Cooling Towers) of Title 24 of the Rules of the City of New York Towers. NYC Department of Health https://www1.nyc.gov/assets/doh/downloads/pdf/notice/2016/noa-chapter8-title24.pdf

- ASHRAE (2015) Legionellosis: Risk Management for Building Water Systems. ASHRAE http://www.r2j.com/wp-content/uploads/2017/10/ASHRAE-188-2015.pdf

LAST UPDATED: June 3, 2018

This document is a good sumary of the very conventional means and methods for addressing the presence of legionella in water systems, most of which are mediocre in their effectiveness. The research of the past 5 to 10 yrs from people such as Nicholas Ashbolt Ph.D and Joe Falkinham Ph.D suggests the need to address the presence of biofilm in the water system.

Ashbolt’s work on identifying the Biofilm-Legionella-Amoeba cycle, whereby amoeba feed off legionella in the upper layers of the biofim, thus providing a reproductive vector, a protection vector, and a transportation vector for the legionella bacteria.

Recent work has also demonstrated that chlorine and derivative products can harden the outer layers of the biofilm that has developed on the internal components of water systems, and so whilst addressing legionella in the upper layers of such biofilm, provides a protective shield for legionella in the deeper layers of such biofilm.

This work shines a light onto the need to better bioengineer the internal aspects of water infrastructure to minimize / eliminate the presence of biofilm which harbors the legionella so that amoeba don’t have such an opportunit.

That incidents of legionalla are increasingly in premise water systems, especially of aging infrastructure, resulting in contraction through aspiration from tap faucetts and shower heads, demonstrates the need for alternative, safe, alternative approaches. Joe Falkinham’s paper on the possible use of probiotics as such a means for addressing the presence of legionella in premise water systems represents the sort of mindset necessary to truly address this problem.